How Automated Resource Monitoring Improves Construction Profitability

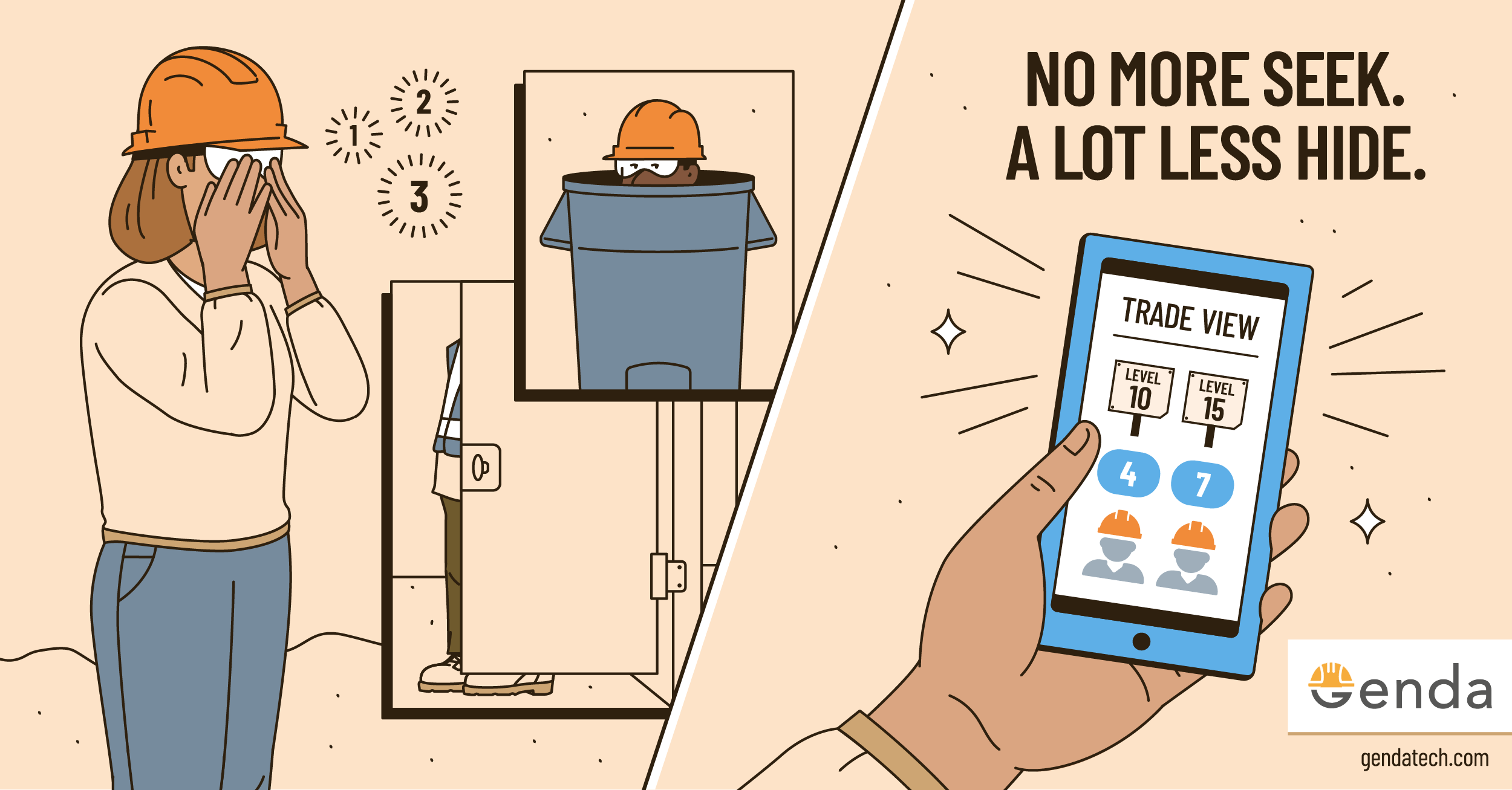

Unplanned activities can account for more than 30% of time spent on construction sites. These on-the-spot improvisations increase spending, lead to rework and contribute to bad workflow. To manage complex projects, construction managers need a better way to witness site activities and to communicate to relevant parties what needs to be done.

Analysis shows a critical requirement of effective project management is easy sharing of vital information, such as the location of construction resources: labor, equipment and materials. With the right strategy, careful resource monitoring can result in:

- Improved productivity.

- Less waste.

- Higher margins.

- Better quality.

Deciding what to monitor

Achieving these benefits, however, requires selecting a technology partner that optimizes efficiency by supplying a solution, instead of only providing data. It also requires a strategy detailing what is monitored.

Partly because of a lack of resource location transparency, construction efficiency lags that of other industries. In 2017, McKinsey estimated that gains in construction efficiency were only a third that of the global economy during the previous 20 years, leading to a productivity gap of about 30%. That same size of a shortfall still existed in 2021.

Everything that has a significant impact on the budget and the schedule of a construction project should be monitored. This includes crew members, senior staffers, visitors, materials and equipment. Of these, workforce monitoring should take the highest priority because labor accounts for as much as 40% of a project’s cost. Construction workers also are mobile and play a major part in the roles of materials and equipment.

All resource monitoring is critical, though, as it provides data required for continuous improvement of site operations and for informed decision-making. In lean methodologies, this is the “check” part of “plan-do-check-act.” Checking that what is done is the right thing at the right time can lead to a threefold improvement in project completion ahead of schedule and to a 1.8-times increase in a project’s chances of completion under budget, according to the Lean Construction Institute.

Resource monitoring combines software with physical presence, whether it be in the form of manual reports, internet of things devices for automated monitoring or infrastructure to connect everything together. Field managers are often busy, so resource monitoring should be as frictionless as possible. The same is true for reporting and data analysis, which should be available on the go so workers can use them when walking a site.

Read how current construction leaders like ANDRES Construction are implementing the latest tech to insure less risk, more valuable insights, and less waste. Download the paper by entering your email below.